EPC+O MODE

On the basis of the above production lines, we can also provide general contracting services integrating design, procurement, construction + modern operation and maintenance management, pre-operational layout, project planning, design and engineering construction are all carried out around the operation side, the whole process of operation is planned and coordinated to realize the low-cost operation of the whole life cycle of the project, and effectively promote the maximization of the overall benefit of the project.

-

Engineering

Overall project planning

Covers: planning of production line equipment, project staffing, office facilities, water and electricity equipment, dust removal, noise reduction and sewage equipment, etc.

-

Procurement

Project equipment procurement

Covers: production line main equipment, belt transportation system, central control system, sewage treatment system, dust removal and noise reduction system, etc.

-

Construction

Project construction

Covers: factory construction, production line equipment infrastructure, dust removal, noise reduction and sewage system construction, installation and testing, technician training, etc.

Entering the EPC field

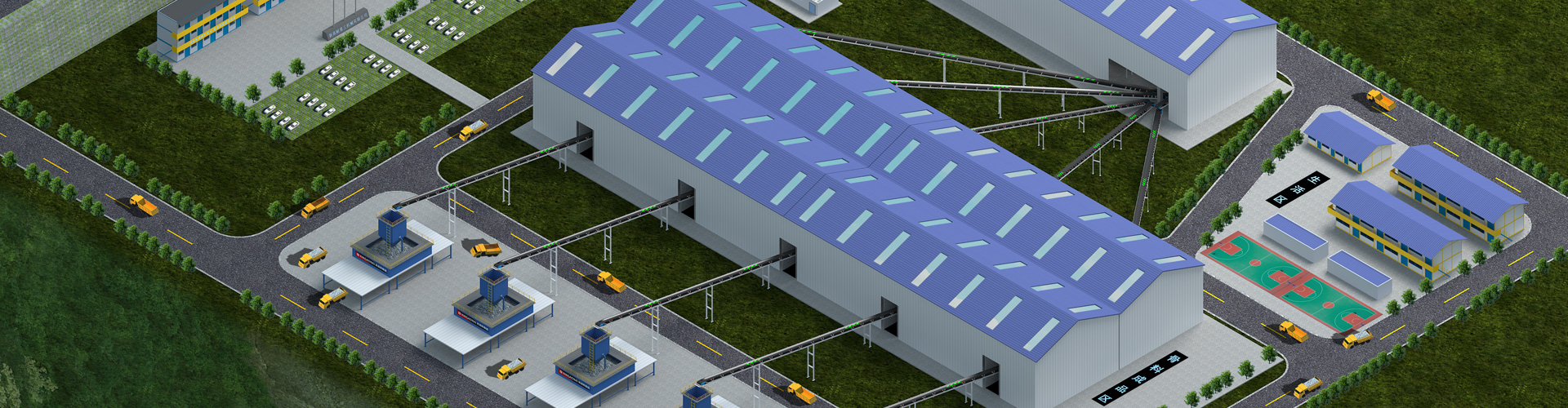

With its superior hardware facilities, strong production and processing strength, innovative scientific research strength, and increasingly perfect service system, our company has officially entered the field of EPC project general contracting and has rapidly grown into a new force in the industry that cannot be underestimated.

Green intelligent Mine EPCO

Smart Mine Management System

Intelligent warehousing and delivery system

Environmental Protection System

EPC Project advantages

-

01

Clear scope of work and responsibilities.Contractors take most responsibilities and risks happened during construction.

-

02

Almost fixed total contract price and project period, so the investment and construction period are relatively clear,easy for fee and schedule control.

-

03

Adopting an EPC project is good for drawing on strengths of each management party and achieving every goal of the project.

-

04

Owners can be free from various trivial things and put their eyes on key points so as to ensure smooth proceeding of projects.

EPC Project case

700-800tph granite crushing and sand making production line in Indonesia

1500tph large-scale sand making production line in Colombia

400-450tph high-quality sand and gravel production line in Poland

500tph limestone sand making production line in Argentina

+8617761642222

+8617761642222